Miksi mennä muualle, kun Jämsässä jää enemmän viivan alle?

Jämsässä elämisen ja yrittämisen kulut ovat pienemmät kuin muualla. Täällä elävään maaseutuun yhdistyy matkailupalveluiden tarvitsema asiakasvirta, teollisuuden tarpeisiin kehitetty infra ja kestävää kiertotaloutta tukevat ratkaisut ja ympäristö.

Yrittäjän palvelut – Apua ja tukea liiketoimintaan/Yritysneuvonta

Hyödynnä osaamistamme yritystoiminnan kehittämiseen ja rahoittamiseen – maaseudun tukipalveluita unohtamatta.

Yrityspalvelut

Sijoitu Jämsään -Säästä kuluissa, voita sijainnissa

Jämsässä kehittämme matkailua ja uudistuvaa teollisuutta. Tutustu yritysalueisiin, tontteihin, toimitiloihin ja käynnissä oleviin kehittämishankkeisiin.

Sijoitu Jämsään

Työpaikat ja työllistyminen – Uusi urapolkusi Jämsässä

Löydä Jämsän avoimet työpaikat tai kouluttaudu uusille urille Jämsässä.

Työpaikat ja työllistyminen

Yrittäjyyden ammattitutkinto verkossa jämsäläisille virittettynä

Aloitus ja suunnittelutilaisuus järjestetään 10.4.2024 klo 16:15 – 18:00 Jokivarren puukoululla, Kelhänkatu 8, Jämsä.

Yrittäjyyden ammattitutkinto tarjolla verkossa jämsäläisille viritettynä

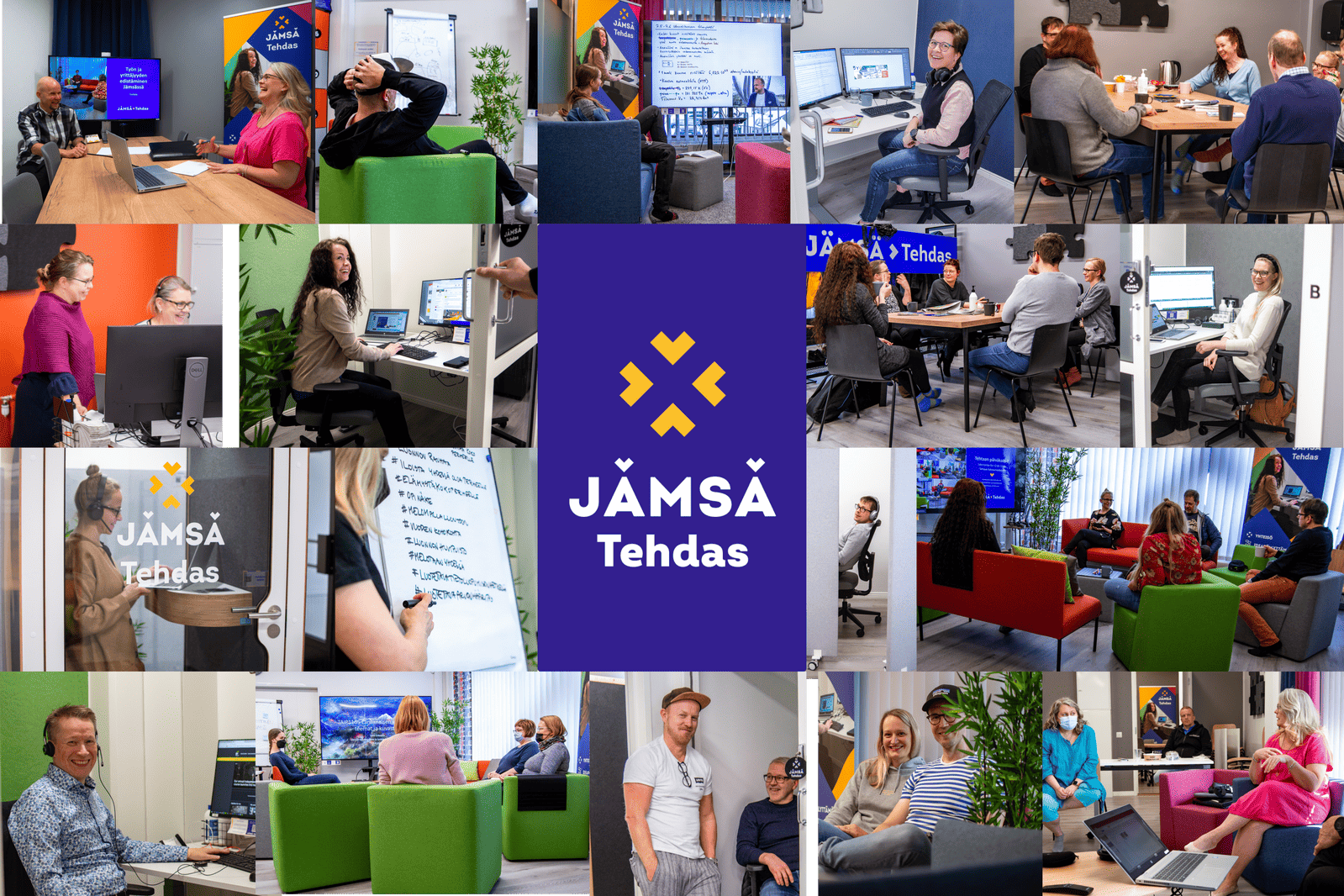

Jämsä Tehdas – Tilat etätyölle ja yhteiseen työskentelyyn

Sanovat, että Tehtaalla puitteet työn tekemiseen ovat jopa paremmat kuin omalla työpaikalla, kotitoimistosta puhumattakaan. Miksi tehdä töitä kotona?

Parempi työpäiväkokemus

Jämsän kaupungin hankkeet

Jämsän kaupungin elinvoiman rakentamisessa elinkeinoelämän kanssa yhteistyössä toteutettavat hankkeet ovat erittäin tärkeässä roolissa.

Jämsän kaupungin hankkeetTapahtumia yrittäjille

-

8.5.2024

08:00 – 09:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

📌Joka kuukauden 2. keskiviikko klo 8:00–9:00Yrittäjien aamukahvit on Jämsän kaupungin ja Jämsä Tehtaan yhdessä järjestämä aamutapahtuma, jossa kahvin lisäksi tarjolla on keskusteluja ja kohtaamisia.Keskustelua ajankohtaisista...

-

13.5.2024

17:00 – 19:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

Yrittäjä saattaa kokea työnsä ja olonsa joskus hyvin yksinäiseksi, ja juuri tähän tarpeeseen Tehtaan vertaisryhmä pyrkii vastaamaan. Tule inspiroitumaan, jakamaan kokemuksia ja oppimaan yhdessä.Yrittäjien vertaisryhmässä voit...

-

16.5.2024

09:00 – 15:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

Tule tapaamaan TE-Palveluiden yritysasiantuntijaa ilman ajanvarausta. Asiantuntija paikalla Jämsä Tehtaalla torstaina 16.5. klo 9-12 ja 13-15 välisinä aikoina.Keskustelut voivat liittyä muun muassa seuraaviin teemoihin:- Alkavan...

-

28.5.2024

08:00 – 10:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

Kasvun kahvit on Jämsä Tehtaan tapahtuma, jossa innostutaan yhdessä yritysten kehittämisestä,Vuoden 2024 tulevia teemoina ovat mm. asiakasarvo ja tuotteistaminen, toimeenpano ja johtaminen, myynti ja markkinointi. Tämän lisäksi...

-

Polku yrittäjyyteen -info ja sparraus

29.5.2024

15:00 – 17:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

Vinkkejä yrittäjäpolun alkuun starttiyrittäjille ja yrityksen perustajille.Monet asiat askarruttavat mieltä siinä vaiheessa, kun ajatus yrittäjyydestä alkaa itää. Mistä lähteä liikkeelle, mistä löytää apua, entä voiko...

-

12.6.2024

08:00 – 09:00

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

📌Joka kuukauden 2. keskiviikko klo 8:00–9:00Yrittäjien aamukahvit on Jämsän kaupungin ja Jämsä Tehtaan yhdessä järjestämä aamutapahtuma, jossa kahvin lisäksi tarjolla on keskusteluja ja kohtaamisia.Keskustelua ajankohtaisista...

-

11.6.2025 – 12.6.2025

Jämsä Tehdas -etätyötila, Jämsä Tehdas -etätyötila, Koskentie 6, 42100 Jämsä

Kesällä 2025 tärähtää jotain suurta ja ennen näkemätöntä.Jämsä Symposium kokoaa Jämsään linkittyviä osaajia tarinoiden, yhteisen keskustelun, oppimisen, verkostojen ja yhteistyön äärelle.Lue lisää tapahtumasta:...

Täällä osataan ja onnistutaan – Kehitämme matkailua ja uudistuvaa teollisuutta kestävästi

Löydä yhteistyömahdollisuuksia Himoksen kehittyvästä matkailukeskittymästä tai uusiutuvan teollisuuden ja kiertotalouden parista. Tutustu kärkihankkeisiimme ja

KehityshankkeetHyödyllisiä linkkejä

Koulutusyhteistyö työelämän tarpeisiin

Meillä Jämsässä ymmärretään työelämää ja yritysten tarpeita. Siksi koulutuksissamme tähdätään työhön, ei tutkintoon.

Yrityshakemisto

On täällä muitakin osaavia yrittäjiä. Tutustu yritysverkostoomme!

Yrityshakemisto Ulkoinen linkki

Jämsän alueen vapaat toimitilat ja yritystontit

Katso tarjonta tai ilmoita vapaana oleva toimitila tai yritystontti.

Vapaat toimitilat ja yritystontitNeljä hyvää syytä sijoittua Jämsään

19 285

Väkiluku 03/2023

16 ha

Toimivia tiloja ja rakennusvalmiita tontteja teollisella infralla.

1300

Yritystoimipaikkaa matkailusta puuteollisuuteen.

220

Vapaa-ajan viettopaikkaa

Ajankohtaista yrittäjille!

Keski-Suomen Kasvupolku® -ohjelmaan valittiin mukaan 15 yritystä. Jämsäläisiä yrityksiä on mukana peräti kolme.

-

Yrittäjyyden ammattitutkinto tarjolla verkossa jämsäläisille viritettynä

POKE (Pohjoisen Keski-Suomen ammattiopisto) yhteistyössä Jämsän kaupungin kanssa järjestää yrittäjyyden ammattitutkinnon verkossa Jämsäläisille viritettynä.

-

Osuuskauppa Keskimaan huoneistohotellin rakennushankkeen aliurakat

Jämsän kaupunki ja Lapti Oy järjestävät infotilaisuuden rakennusalan yrityksille ja alihankkijoille 27.3. klo 14-16 Jokivarren puukoululla, Kelhänkatu 8, Jämsä.

-

”Kaikki lähtee ihmisistä ja vuorovaikutuksesta”

Asuntovaunu Himoksella ja työpäivä Jämsä Tehtaalla – Säästöpankkikeskuksen liiketoimintapäällikkö Riku Rissanen on yksi Jämsä Tehtaan kausikäyttäjistä.

-

Kasvuyritykset ja rahoittajat kohtasivat Himoksella

Suomen Yrityskehitys ja Jämsän kaupunki järjestivät toista kertaa Rahoituspaneelin Jämsän Himoksella maaliskuun 1. päivänä 2024.

Osataan sitä muuallakin, muttei niinkuin meillä!

Elämä on yllättänyt monellakin tapaa Maria Lampisen, joka asuu nyt Koskenpäällä ja on Mainoslahjaverkkokaupan yrittäjä.

-

Omin käsin luotua kauneutta

Koi Design on jämsäläinen koruyritys, jonka mallistossa hehkuvat hopea sekä monet värit. Yrittäjä Tiina Hälikkä muutti Oulun seudulta Jämsään syksyllä 2022.

-

Auteriset ovat yrittäjinä moniosaajia

Länsi-Himoksen juurella seisoo jyhkeä Rinne-ravintola, jota luotsaa aviopari Jukka ja Tytti Auterinen. Pariskunnan laaja kokemus yrittäjinä on vertaansa vailla.

-

Perinteikäs perheyritys Ollin Sora Oy täyttää 30 vuotta

Syntymäpäiviään viettävä perheyritys Ollin Sora Oy tarjoaa maa-ja kiviaineksen myynnin lisäksi maanrakennusta, tienhoitoa, purkutöitä ja teiden parannustöitä.

-

Nisula Forest Oy – huippuluokan tuotekehittelyä ja kansainvälistä kauppaa

Jämsän Hallissa sijaitseva Nisula Forest on piakkoin ottamassa käyttöön 1500 neliön tuotantotilojen laajennusosan. Investoinnin suuruus on 2,5 miljoonaa euroa.

Täällä arvostetaan työtä ja yritteliäisyyttä!

Apukädet ovat aina lähellä. Ota rohkeasti yhteyttä, kysyvä ei eksy tieltä!

Marko Leppänen

yrityspalvelupäällikkö

Joonas Nurminen

yrityspalvelupäällikkö

Petteri Koskinen

yhteisömanageri / Jämsä Tehdas

Visa Törmälä

yrityspalvelupäällikkö

Etsitkö työpaikkaa tai oletko työntekijöitä vailla?

Työllisyyspalveluiden osaava henkilökunta auttaa sinua, ota yhteyttä!